The neck and bottom of each bottle is removed using a diamond-blade saw, and then the remaining body of the bottle is cut into two halves down the middle

To make the pieces flat, the glass is placed in a kiln and brought up to 1450 degrees Fahrenheit gradually, and then slowly cooled back to room temperature.

After an eight hour cycle in the kiln, the glass is flattened through a process called "slumping," and can be cut apart and used for the mosaic

August 1, 2016...We clear the grounds so we can begin the mosaic. The wall is in the center of the property, and stands empty with the exception of a few bushes, which are dug out with gusto by the crew.

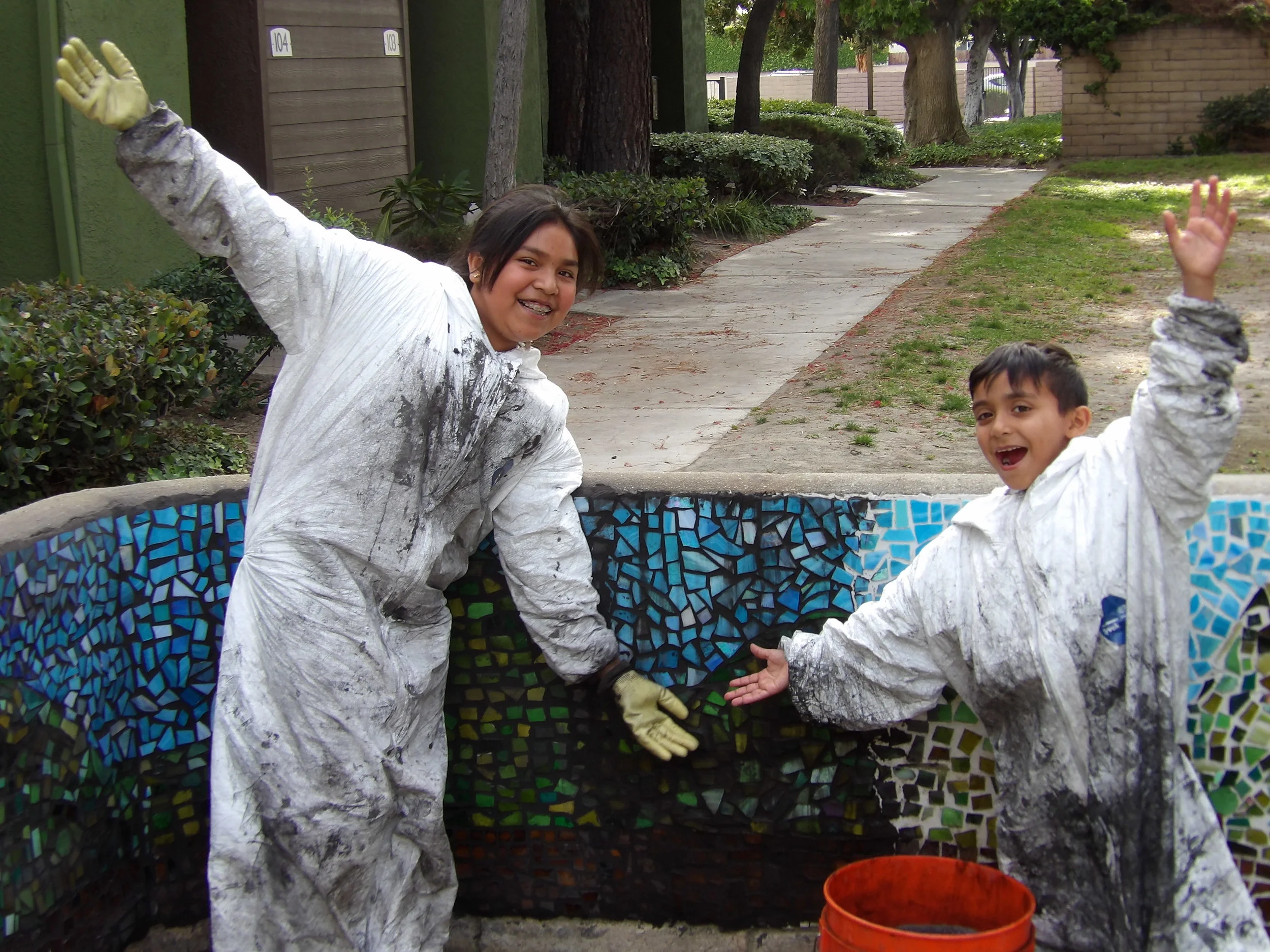

Medina and Bianca getting ready to mix the thin-set mortar to prep the wall for mosaic-making

The wall is prepared by spreading a thin layer of white mortar on the surface so that it creates a continuously smooth and clean surface to glue the glass onto

Bianca, cutting and placing the first squares of flattened bottle glass onto the wall to begin the mosaic. It has taken months to get everything ready and plan for this project, and will be be weeks and weeks more to its completion.

The wall is two feet tall and 120 feet long. It's a big project, and will take us months to complete